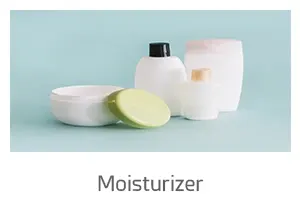

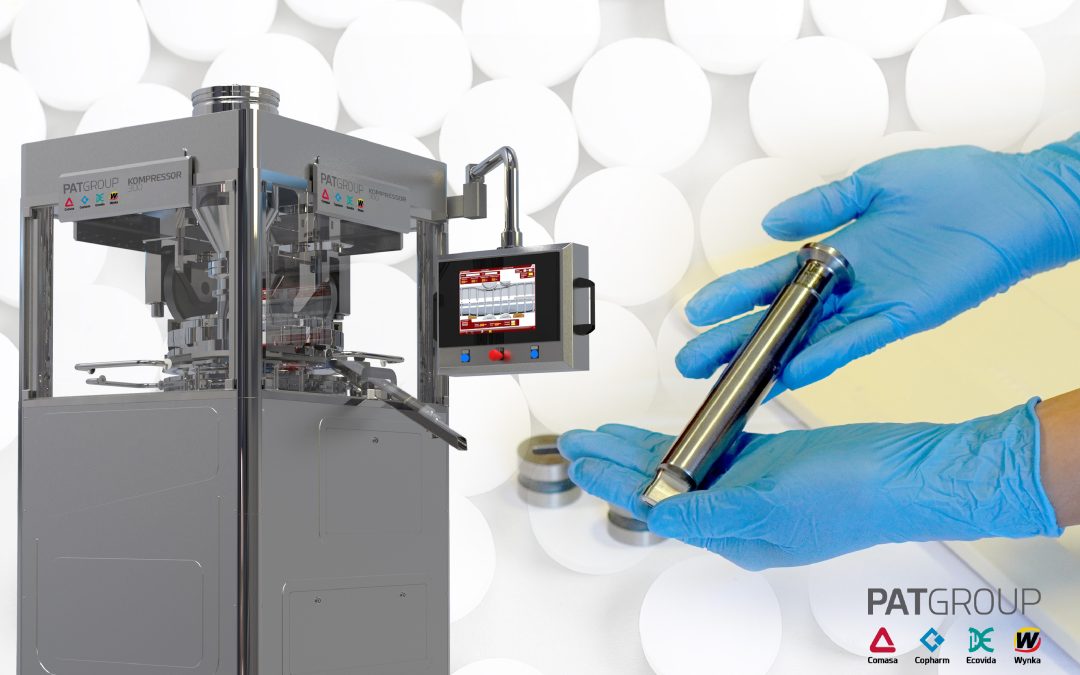

This methodology enables the production of particles with specific characteristics, such as size and shape, which are fundamental to ensuring medication bioavailability. Fluid bed granulation combines drying and particle formation into a single process, reducing production time and operating costs.

With precise control of parameters such as temperature and humidity, fluid bed granulation minimizes dust formation while maximizing product recovery—a key factor in producing active compounds that require careful handling to maintain stability.

One notable advantage of this technology is its adaptability to different formulations, allowing pharmaceutical companies to tailor their processes to the specific characteristics of each ingredient.

PAT Group provides comprehensive consulting for implementing fluid bed granulation solutions, ensuring clients maximize the benefits of this advanced technique. Our team of experts collaborates with industry professionals to develop customized processes that meet the highest quality standards for the final product.

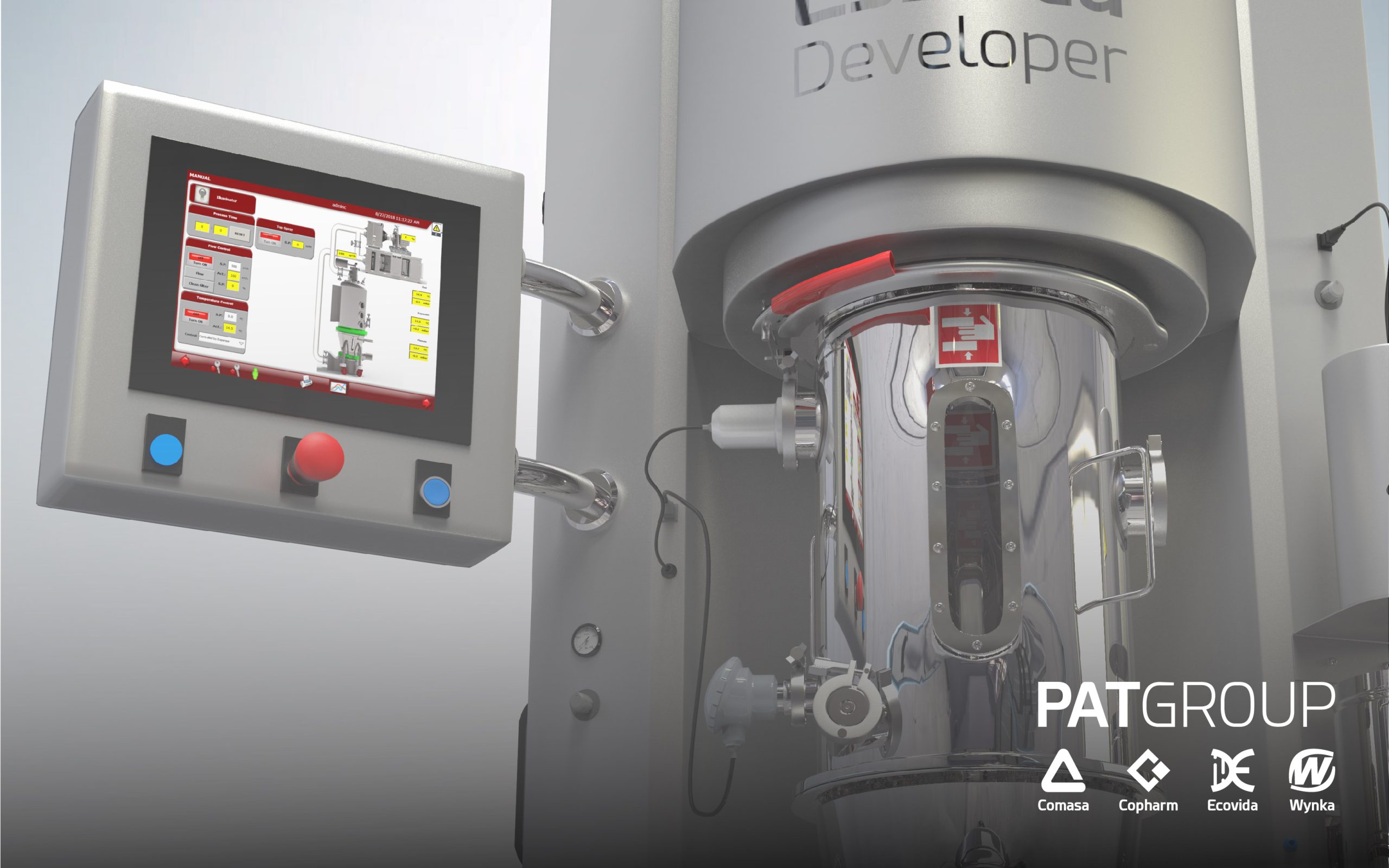

Thanks to its optimized control and automation, the ESSICCA Fluid Bed Dryer is the ideal choice for implementing this technique. This equipment determines the optimal airflow based on the minimum fluidization velocity (Umf) and automates the drying process using predefined recipes.

Furthermore, it estimates the drying endpoint by continuously monitoring product temperature, ensuring a consistent drying phase at a constant speed.

With the ESSICCA, pharmaceutical companies can further optimize their granulation processes, enhancing product quality while reducing operating costs. At PAT Group, we are committed to excellence in pharmaceutical production, offering innovative and customized solutions for every client.