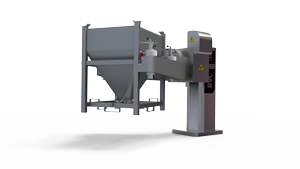

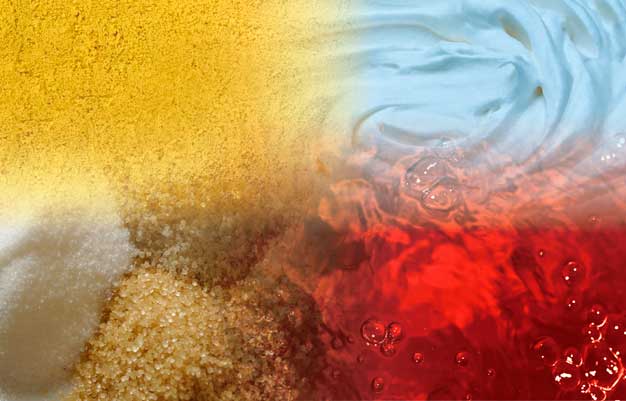

The purpose of this weighing station is to form the batch according to the previously edited recipe, controlling the entered weight of each raw material and then unloading the complete formula in a mixing or kneading equipment.

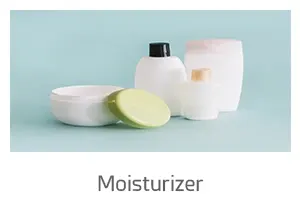

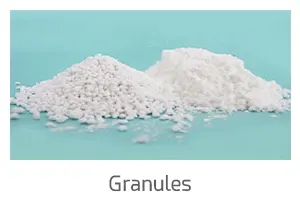

The raw materials to be dosed and weighed can be obtained from a Big-Bag, a BIN, or a silo.

Advantages:

-

Control and registration of recipe (formula).

-

Control and record of accumulated product level.

-

Control of the weight of the stored raw material.

-

Warning for low level of product in silo, Big-Bag, BIN, etc.

-

Remote flush valve command.