In recent years, this powerful tool has transformed the paths for addressing production challenges in the pharmaceutical industry. This model is redefining excellence standards in drug manufacturing.

What does a productivity circle entail?

It is a space where teams can freely exchange ideas, seeking those that can enhance factory operations. One of the metrics for evaluating performance is OEE (Overall Equipment Effectiveness), calculated using the formula A x B x C:

- A (Availability): represents the time dedicated to manufacturing a batch relative to the total time of the line dedicated to that batch.

- B (Speed): refers to the actual process speed compared to the nominal speed of the line.

- C (Quality): indicates the proportion of correct units relative to the total units produced.

For years, productivity circles have been a vital resource for engaging all levels of the organization in the constant pursuit of improvement. These initiatives focus on seemingly small actions but generate an impact on final results.

In the pharmaceutical industry, productivity circles have proven their effectiveness. Through advisory programs for identifying improvement opportunities, many companies have implemented systems to identify and prioritize actions, allowing them to direct efforts toward areas with optimization potential.

This tool for boosting efficiency in manufacturing environments can make a difference in an increasingly competitive market.

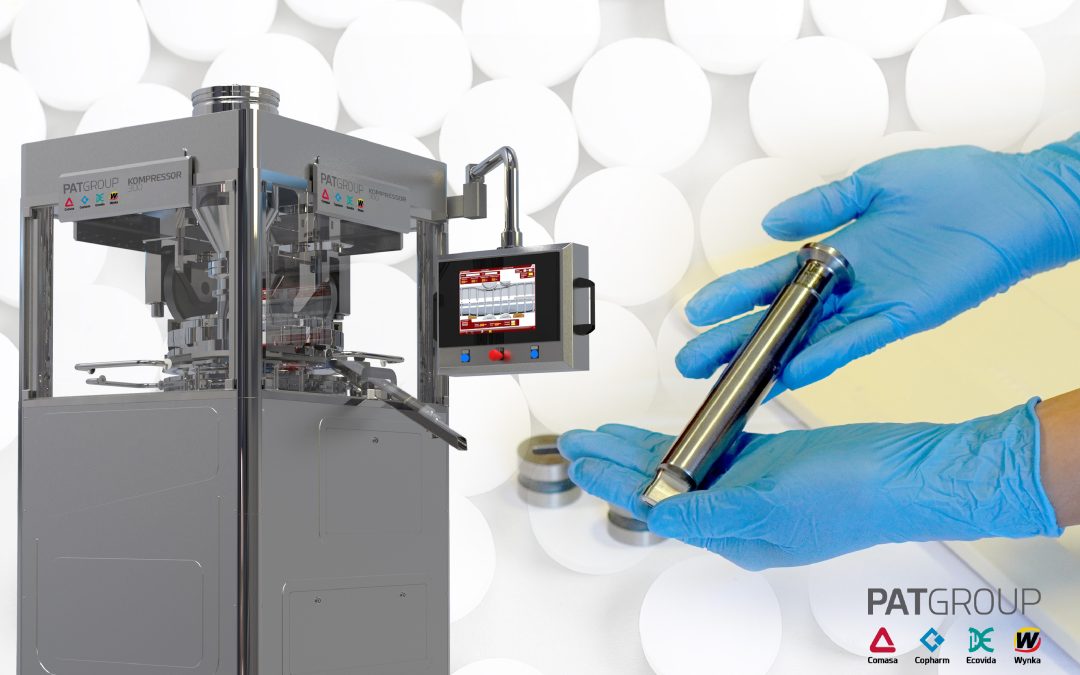

At PAT Group, we offer comprehensive solutions that guarantee scalable, reliable, and traceable processes to improve your business and enhance the lives of your end consumers by providing quality products.

Get an advisory meeting to identify your needs and find a tailored response alongside our experts with deep know-how in pharmaceutical development.