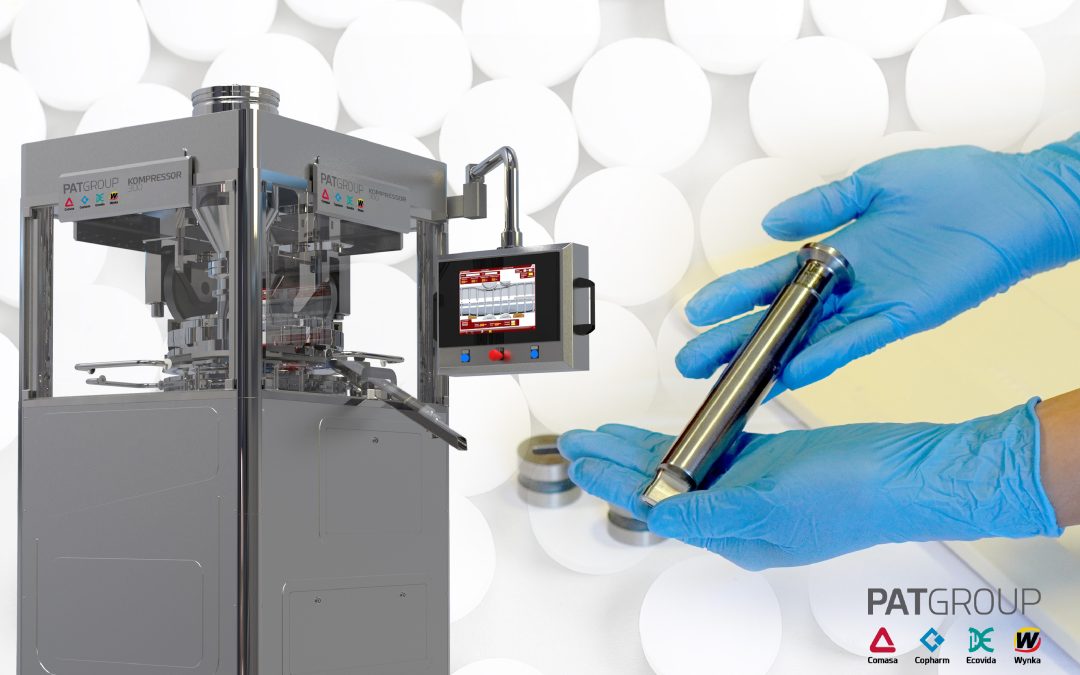

Weight variation is a common problem that affects manufacturing, leading to imperfections in the final product. Rigorous control of this variable will help improve tablet hardness and friability.

Tips to avoid weight variation in tablet manufacturing

It is primary to review the following aspects to analyze the manufacturing conditions and optimize the process.

- Tablet press parts maintenance and replacement: Checking the wear is the first step toward detecting any possible errors. The timely replacement of the turbine and the filling guide guarantees long-term, proper functioning.

- Punch tooling failures: It is essential to clean the dies, remove traces of sticky powder and lubricate the pieces before storing them.

- Quality of the semi-finished product: Filler powder influences tablet weight significantly and will vary if it is too hard, moist, rough, or fine. Special attention throughout each process stage is fundamental to achieving weight accuracy and ensuring quality.

How can we help you solve this type of productive issue?

We work to offer technological solutions to the daily challenges faced by the pharmaceutical industry.

Our R&D specialized professionals, with the experience of our technical staff, will help you with any of your needs in equipment design, production process, and productive efficiency.

Keep in touch: