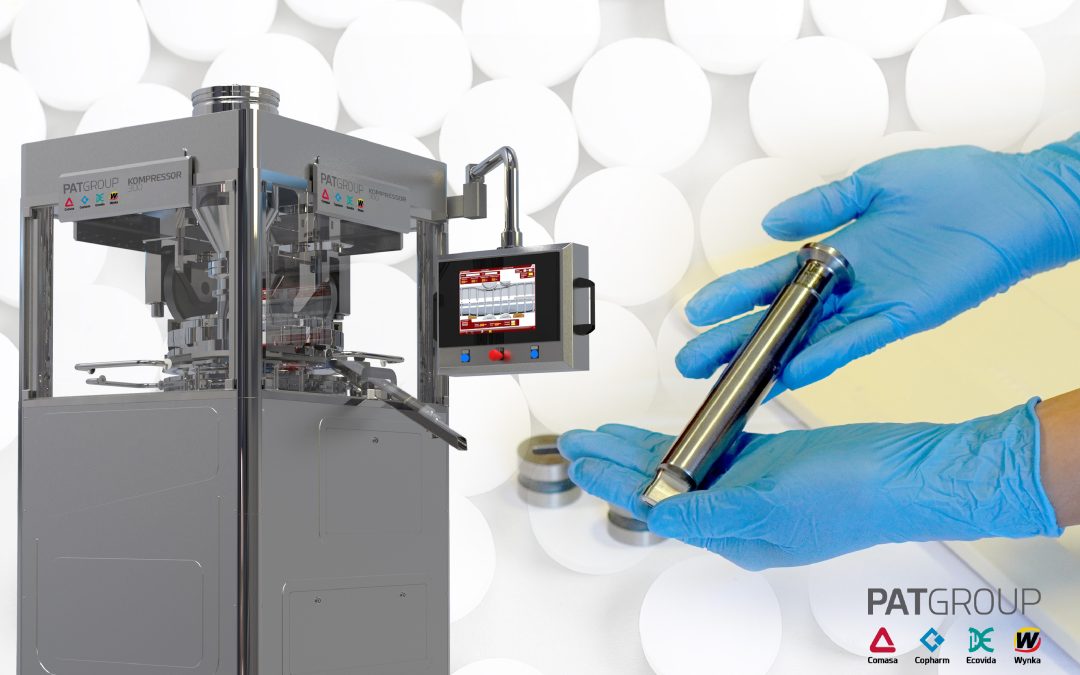

In the pharmaceutical industry, the production of oral dosage forms relies on three processes: wet granulation, dry granulation (by roller compaction), and direct blending.

These processes are more than simple manufacturing stages; they constitute fundamental pillars in optimizing the characteristics of pharmaceutical products and contribute significantly to the effectiveness and final quality of medicines.

Types of Granulation

Dry granulation is ideal for compounds sensitive to moisture and heat since it does not require the presence of liquids, making it energy-efficient. Uniform granules are produced through compaction and size reduction, facilitating subsequent tablet compression.

On the other hand, wet granulation involves adding a liquid solution to powders, facilitating granule formation through agglomeration. This technique is adequate for water-sensitive drugs and provides an effective alternative to dry granulation.

Understanding these granulation technologies is vital to guarantee quality and efficiency in oral dosage form production. Choosing between wet and dry granulation depends on the product characteristics and manufacturing needs.

At PAT Group, our mission goes beyond providing equipment and services; we are committed to being strategic partners in your industry, offering comprehensive solutions that precisely and efficiently address every challenge in the production process, from selecting granulation technologies to implementing innovative practices.