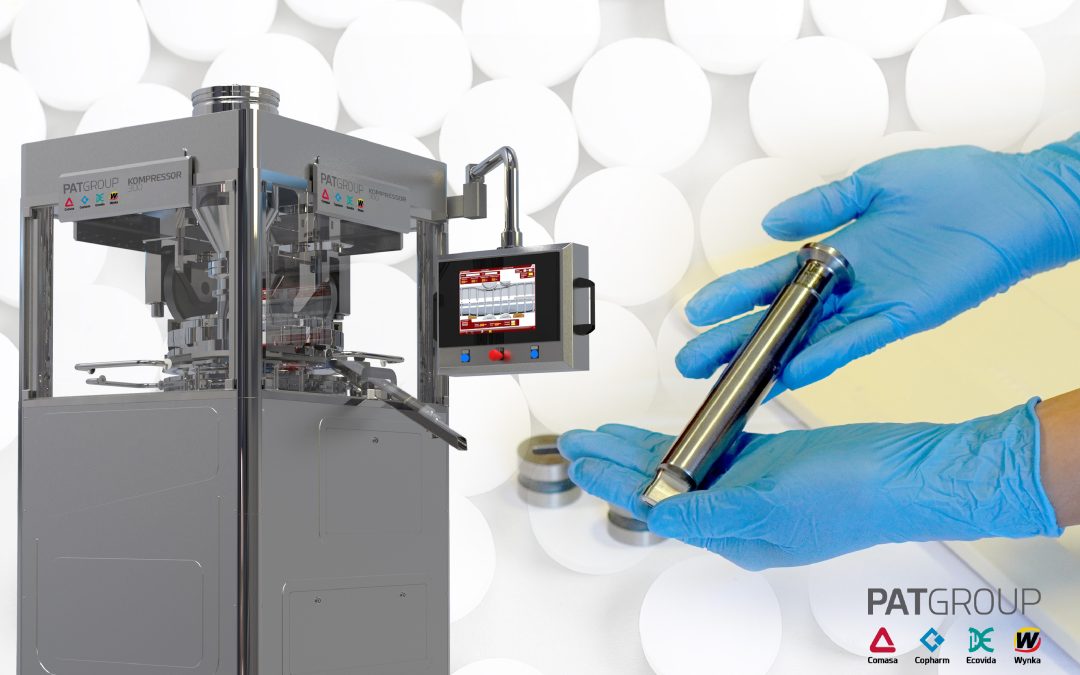

Our mill operation relies on a high-speed rotating impeller that collides, fragments, and tangentially propels the material toward the holes of a sieve or cone selector. The impeller’s speed and design, the size and arrangement of the cone selector’s holes, and the separation between the impeller and cone walls are independently adjustable to achieve the desired particle size.

Tool-less Disassembly

Thanks to its ingenious design, the CPS Line simplifies maintenance and cleaning tasks by allowing complete tool-less disassembly, including its panel. This feature becomes an exceptional solution for pharmaceutical companies seeking versatile, efficient, and easily maintainable milling equipment.

Tailored Solutions to Your Needs

Our catalog of milling technologies adapts to specific situations. From the initial development option through an intermediate model, designed for integration into production lines, and to the advanced design with a 40% increased production capacity.

Each project is unique, so our range of solutions aims to provide the answers your project requires. Whether you are exploring new opportunities or seeking a significantly increased capacity, we have personalized possibilities for all your needs.