In every industrial production process, and especially in cosmetic, food and animal nutrition formulations, raw materials and the macro and micro-components of each preparation should be strictly controlled at each stage.

Raw material weighing refers to one of the first and most important timepoints of the production process. At this point, the components are already defined and we need precision tools and equipment to weigh the quantities that will form the compound.

At this manufacturing stage, it is imperative to count on an efficient and reliable method for the successful dosing and incorporation of raw materials.

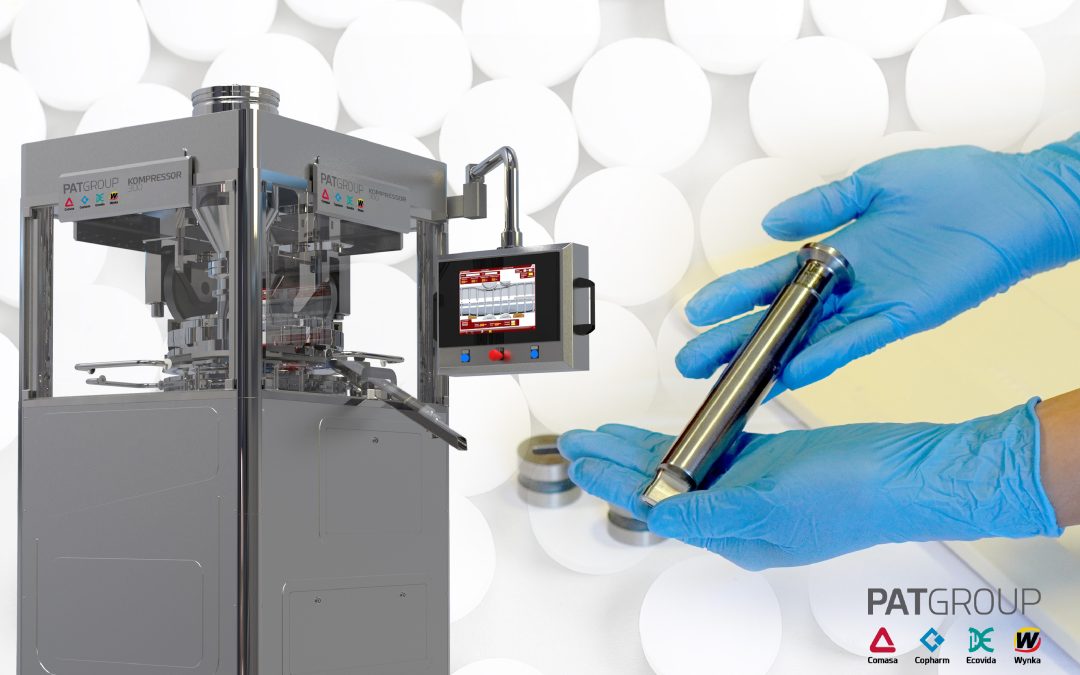

Depending on the needs and characteristics of each product, the following step in the production line will be the mixing, compression, coating or packing process.

In each of these phases, and even more if we are dealing with highly active substances, the use of high containment equipment is mandatory. In particularly vulnerable transfer stations, it is necessary to secure the best protection possible both for the product and the operator.

When the batch is small, weighing could be manual. However, the application of this method in high demand environments, where every industrial process should be optimized to meet a high speed production demand, becomes impossible.

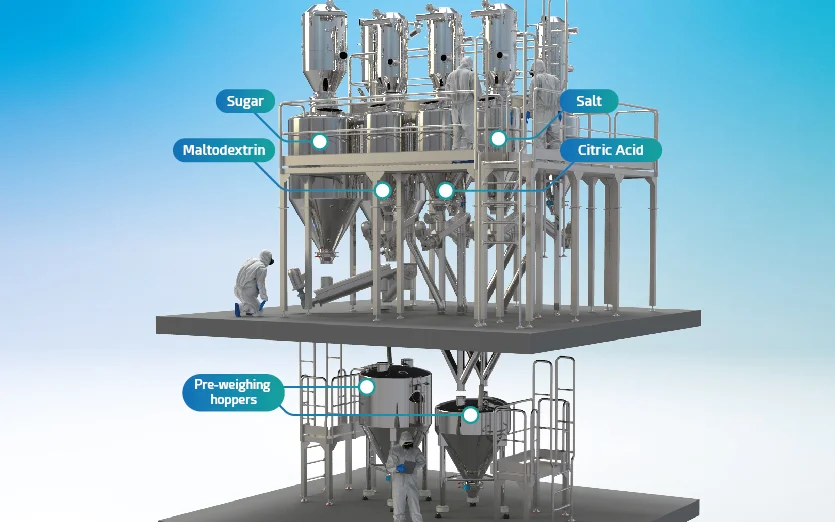

PAT GROUP´s raw material weighing station is a reliable solution for this type of the demand.

It is a modular equipment for the weighing of components, macro and micro-nutrients that can be unloaded either from Big-Bags, bins or silos.

Main benefits of an efficient raw material weighing method

The adoption of precision equipment as an additional element of the productive process brings multiple benefits, including:

Resource optimization

When talking about resource optimization, we refer to the use of every available means so as to get the maximum benefit.

The raw material weighing station provides full control of the materials, enabling the dosed feeding and preventing material wastage.

Besides, the station is fitted with low product level indicator and discharge valve remote command.

Quality improvement

In the pursuit of reaching the standard of excellence in every formulation and product, precision is the key.

The unfailing control and registration of each ingredient proportion is essential to achieve the quality determined in the previous trials.

Product repeatability

The development of a product consists basically in the creation of a first unit to be massively replicated and delivered through the most adequate operating processes.

Using precision methods, you will be able to secure reliable and safe replications of the developed product, thus automating recipes.

Traceability control

In any process, traceability is instrumental to be able to follow and check every step of the manufacturing operation. And that control should be documented throughout the production process in order to create the relevant record.

This task is automatically solved by the raw material weighing station software, that enables to create records for every batch. Optimizing these aspects is fully possible. Both in the transport and dosing of raw materials, it is highly important to avoid the manipulation and improper use of finished products.

All weighing stations may be customized to the specific needs and to enable connection to different applications so as to get a full robust line compliant with the GMP guidelines.

Production improvement requires some investment. However, the return will certainly become effective with the results and the achievement of the desired goals.

Follow us: