Known as “Twinning,” tablet production encounters a recurring issue where two or more tablets become stuck with each other. This defect occurs when two granule particles become trapped in the tablet matrix and are not fully compressed, resulting in a tablet with two overlapping layers, also called a “twin tablet” or “twinning.”

This setback is attributable to various factors, such as inappropriate tablet shape, considerably low compression speed, insufficient atomizing air pressure, or excessive spray rate, among other aspects.

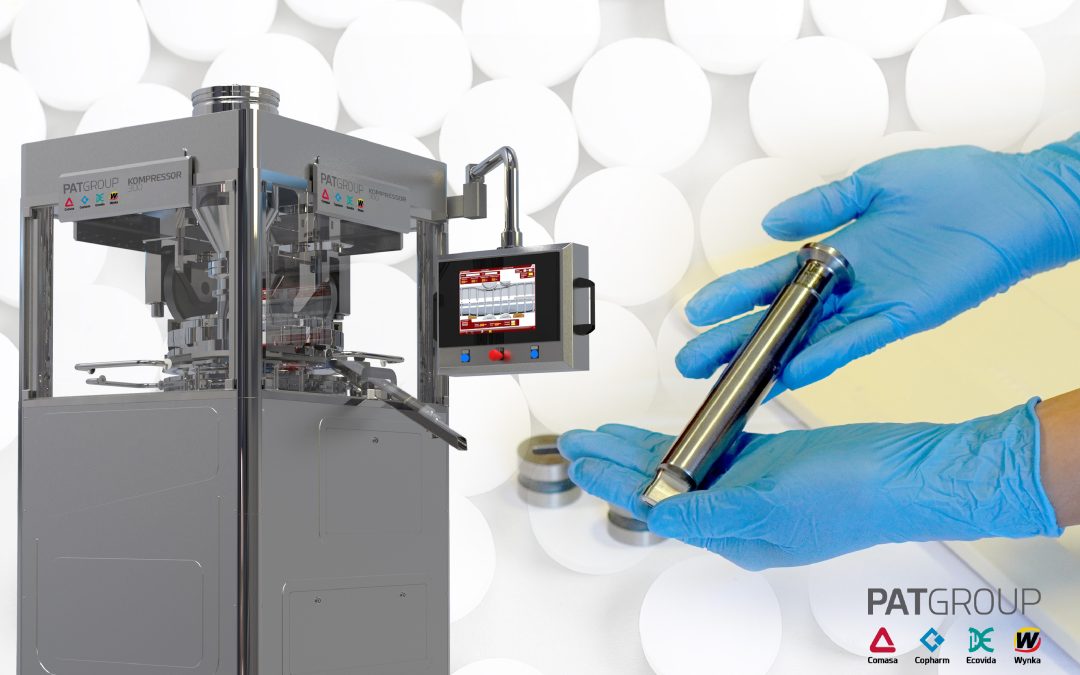

After identifying the challenges posed by Twinning in tablet production, it’s essential to explore strategies to overcome this obstacle effectively. Along with our commitment to providing comprehensive solutions through our wide range of equipment and services, hereunder we will list some feasible solutions to improve quality and avoid Twinning:

- Proper Tablet Design: we recommend opting for a tablet design that eliminates flat surfaces, reducing the likelihood of tablets sticking together during production.

- Atomizing Air Pressure Improvement: adjusting atomizing air pressure to optimal levels ensures uniform spraying, preventing the formation of stuck tablets.

- Spray Rate Control: decreasing the spray rate helps prevent excess moisture in the tablets, which is a factor that contributes to Twinning.

- Drying Process Improvement: in some cases, increasing the drying process through higher inlet temperature or increased airflow rate ensures that the tablets exit the machine adequately dry and free from adhesions.

At PAT Group, we specialize in providing integrated solutions that enhance quality and efficiency in pharmaceutical production. Do not hesitate to contact us to discover the specific solution that best suits the needs of your product.