Why wet granulation?

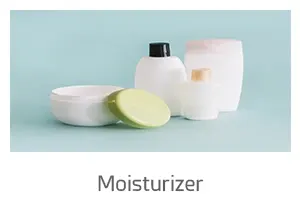

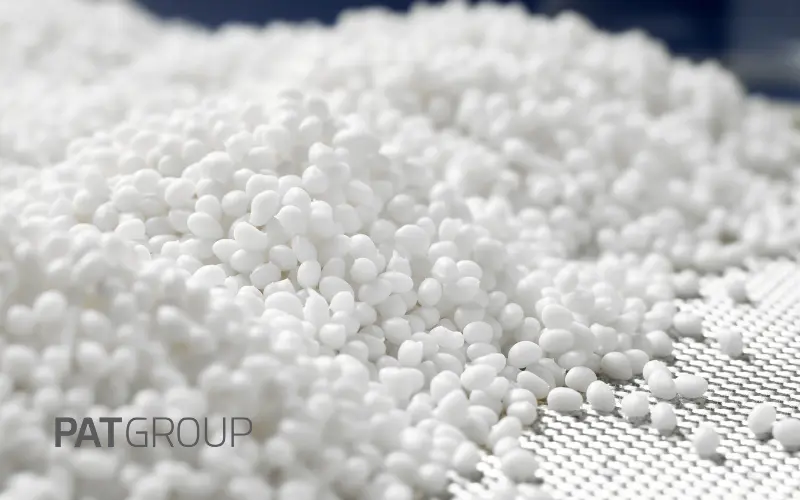

When the powder mixture lacks good compressibility and presents flowability, density, or homogeneity issues, the wet granulation method can be a beneficial alternative for your manufacturing process.

This method’s success lies in achieving an optimal granule endpoint, with characteristics such as shape, mean size, porosity, and resistance suitable for compression or the next unit operation.

Explore the tablet production process through wet granulation

Immerse yourself in a journey to turn powders into high-quality pharmaceutical tablets following the essential steps of this process:

- Sieving. Preparation of the binding solution.

- High Shear mixing: active principles and diluents merge, ensuring uniformity in the mix.

- Wetting and kneading: to obtain a suitable wet mix.

- Conical Mill: wet calibration to ensure granule consistency.

- Fluid bed drying to remove moisture efficiently.

- Conical Mill: dry calibration to achieve the desired particle size.

- Sieving of external components.

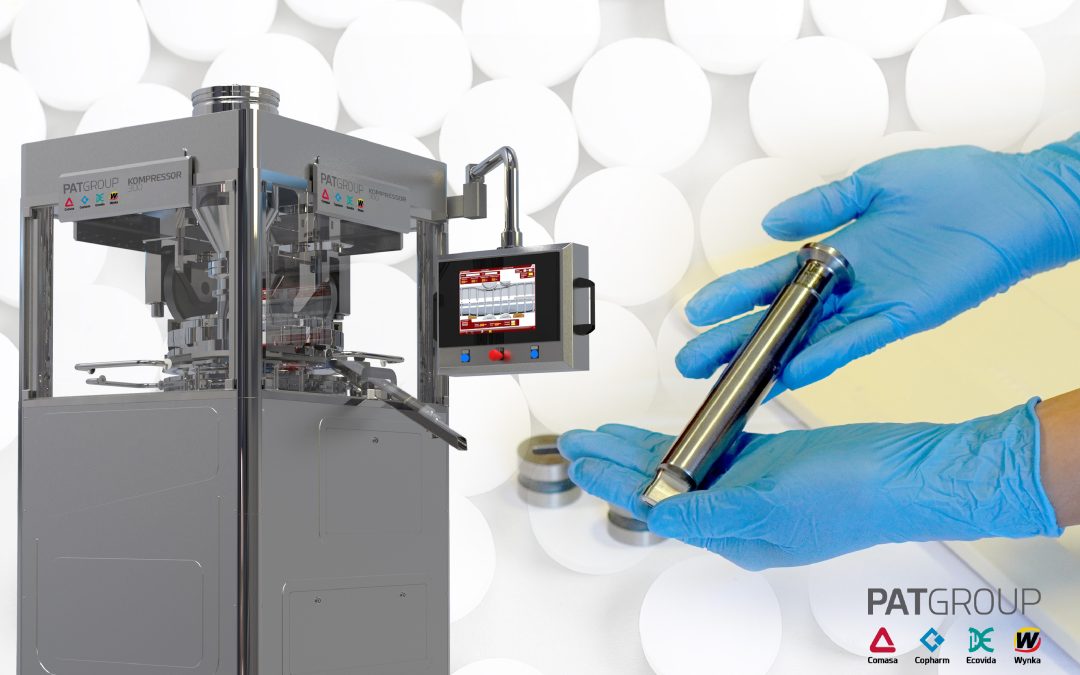

- Final mixing and compression: tablets take shape through the compression process, ensuring consistency and quality.

- Coating (optional): if necessary, a functional or cosmetic coating is applied in this final stage to enhance the appearance or stability of the tablets.

A unique partner

At PAT Group, we offer comprehensive solutions that ensure scalable, reliable, and traceable processes to improve your business and enrich the lives of your end consumers by providing a quality product.

With a laboratory staffed by highly trained pharmaceutical professionals, experts in design and manufacturing, specialized process engineers, and an outstanding customer service department, we are in a unique position to offer comprehensive product development and advisory services that encompass all needs. Our multidisciplinary team combines technical expertise, regulatory knowledge, and a solid understanding of customer needs to deliver innovative and customized solutions that exceed expectations. Trust us to guide you through the entire process, from conceptualization to implementation, ensuring results of the highest quality and customer satisfaction.

Arrange a consultation meeting to identify your needs and find a tailored solution alongside our experts with profound know-how in pharmaceutical development.