The pharmaceutical and cosmetics industries continue to evolve to enhance quality and efficiency in producing semi-solid formulations. With a growing focus on automation and quality control, advanced technologies are redefining standards at every stage of the manufacturing process.

Optimization of processes through reactors and more precise temperature and mixing control systems is a crucial advancement in semi-solids production. These tools enable more efficient integration of ingredients, ensuring perfect consistency from the start. By controlling parameters such as temperature, speed, and mixing time, companies can achieve homogeneous and stable products easier.

In particular, using fat-melting reactors and emulsifying mixers ensures more uniform base melting and greater production flexibility. These refinements allow formulations to be tailored to the specific needs of each product, which is especially important when working with active compounds sensitive to temperature or humidity.

Additionally, transfer reactors and optimized storage systems are improving safety in the transfer of products between process stages. These systems minimize contamination risks and ensure that mixtures are preserved under optimal conditions until packaging, maintaining all properties and guaranteeing their effectiveness until the final moment.

Automation also plays a role in operational efficiency. New production solutions enable remote, real-time control of all process parameters, improving product quality and reducing production times and operating costs. This allows companies to be more agile and respond quickly to market demands while maintaining the highest quality standards.

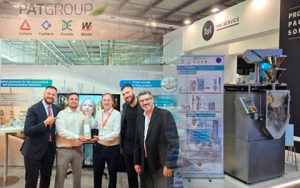

At PAT Group, we are acutely aware of these advancements and their impact on the landscape of semi-solid product manufacturing. Implementing new technologies optimizes production, offering opportunities to create more effective and higher value-added products for the end consumer.