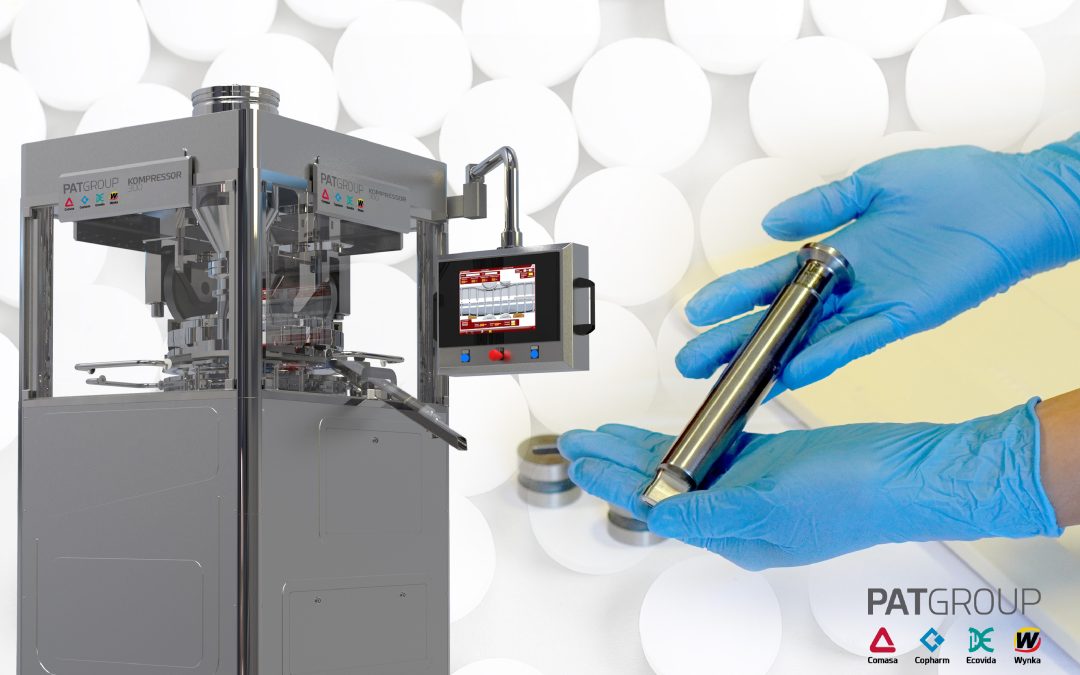

In production, especially in the pharmaceutical, food, and chemical industries, having an EBR (Electronic Batch Record) is essential for regulatory compliance, quality control, reproducibility, and problem resolution.

The Batch Record software optimizes process recording intelligently and effectively, storing and managing all production steps.

By having a detailed batch record, your company can ensure process reproducibility and transform them into a guide for operators and technicians involved in production. Standardize operations and provide clear instructions on the execution of each procedure step, offering the opportunity to identify possible causes of variability or defects.

The EBR system encompasses batch details, raw materials used and their corresponding quantities, manufacturing procedures including equipment and process parameters, quality controls performed during and after production, and deviations or issues detected along with their solutions.

It’s important to highlight that the Electronic Batch Record provides significant value compared to traditional methods, where companies used to record production batches on paper. This tool has largely automated the process and has become a valuable resource for continuously improving procedures.

At PAT Group, we are experts in personalized industrial efficiency solutions to address every need. Our mission lies in turning our clients’ technological challenges into opportunities through comprehensive solutions.

Feel free to request advice on this and other innovative proposals.